-

planning

2016–2018data

usable floor space 685 m2client

Pollmeier Massivholz GmbH & Co. KG, Creuzburgstructural engineering

Jörg van Kann, Frankfurtbuilding services engineering

HKL Ingenieurgesellschaft mbH, Erfurtfire prevention

Hagen Ingenieurgesellschaft für Brandschutz mbH, Erfurtrendering

Cornelsen+Seelinger Architekten -

Apart from water and sunlight, all green plants need carbon dioxide (CO2) for growing. During the day, they withdraw large amounts of carbon dioxide from the atmosphere, store carbon in their plant mass and then release the highly important oxygen. CO2 is a so-called greenhouse gas and highly responsible for the climate change.

To use wood from regional and sustainable forestry as building material is therefore an important contribution to climate protection. Greenhouse gas remains bound in wood products. At the same time, new wood grows on the areas that become available again. Contrary to when the wood is used as firewood, CO2 stays out of the atmosphere for the whole lifetime of the wood product.

One of the forerunners of the development of high-performance wood materials is the Pollmeier Massivholz GmbH & Co. KG.

-

Traditionally, mainly softwood is used as construction material. Though hardwood has a greater stability, for a long time it was technically impossible to make laminated veneer lumber (LVL) out of it. In years of research, Pollmeier has developed an economic manufacturing process and is currently the only manufacturer of laminated beech veneer lumber. This high-performance construction material runs under the name BauBuche. It is manufactured solely from local beech wood from sustainable forestry.

In a new technical center at the company headquarters in Creuzburg, this innovative material is constantly being optimized by an in-house team of researchers. In addition, there are research cooperations with a number universities.

-

The pavilion-like building shows how laminated beech veneer lumber can be applied in real life: All supporting walls (frame, massive or rib design) consist of BauBuche.

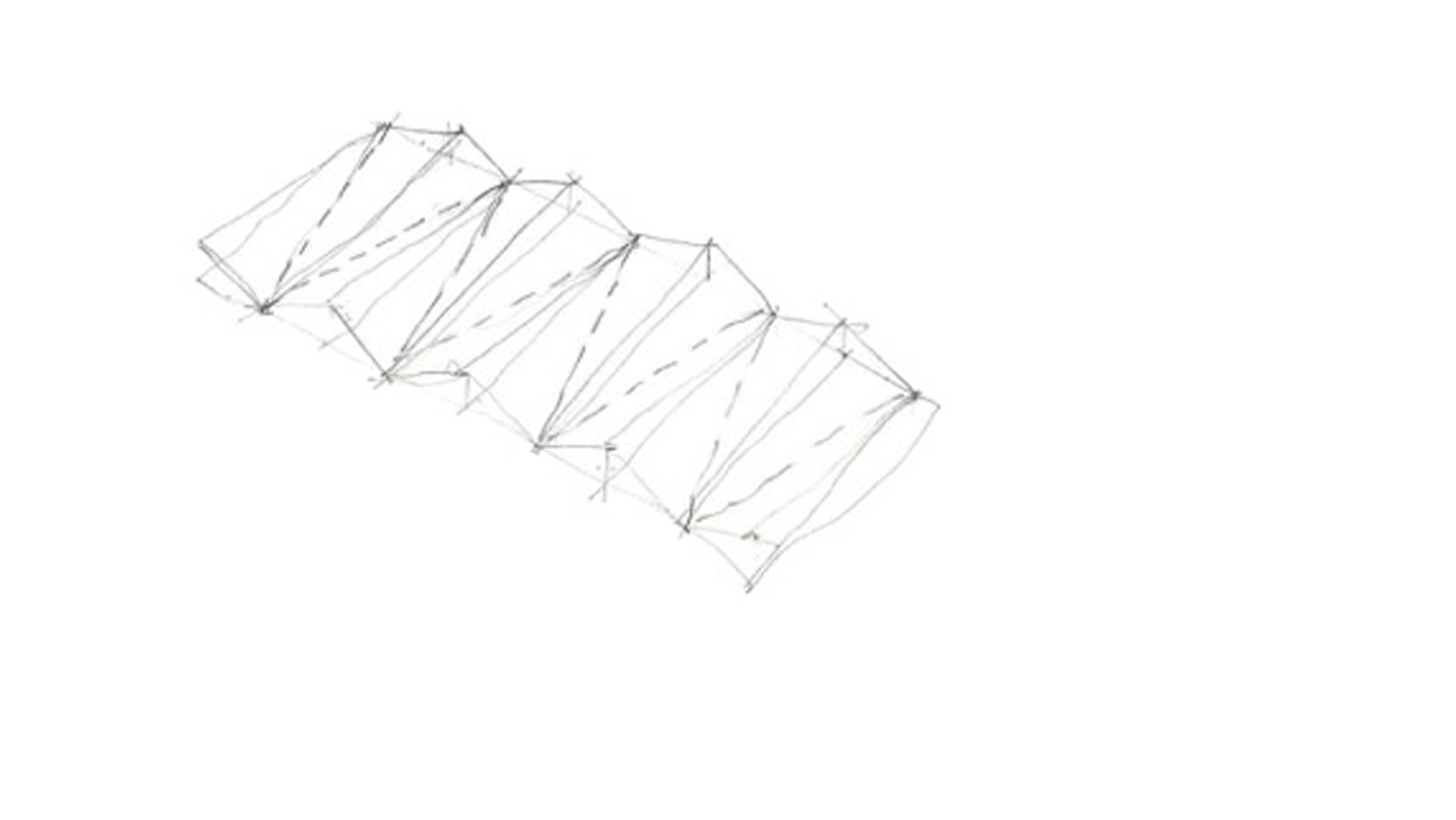

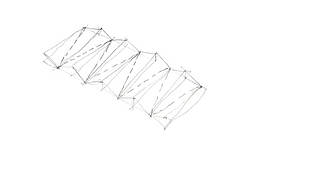

Even the roof structure is built of a folded BauBuche construction. The folded roof structure is the result of a special geometrical division of the construction panel. It can be seen from the inside of the building and largely characterizes its appearance. This way, both visitors and employees can experience the capacity of this new material on an everyday basis.

-

Transparency is the predominant atmosphere in the new technical center: Design department, meeting rooms, workshops and laboratories all open toward the company's own neighboring landscaped park near a small creek. The inviting character of the building fosters communication among employees and visitors and constitutes an important juncture on the company premises between the administration and production buildings.